Archives: Services

I servizi di C.T. Centro Tornitura

I servizi di C.T. Centro Tornitura

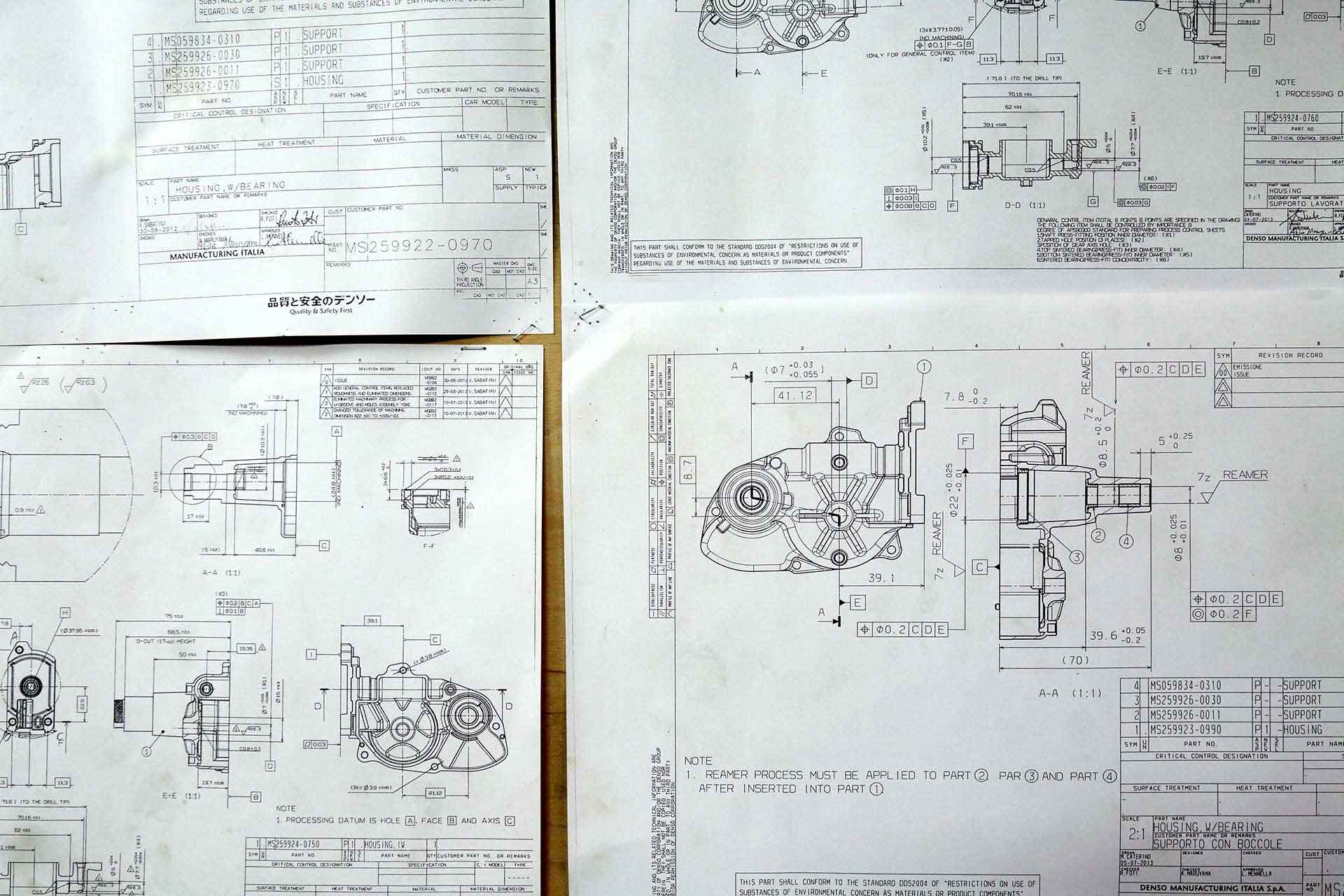

The technical drawings and the requests for offers that come from the customers are examined jointly by the Sales Office and the Technical Office, who quickly make the estimate to respond to the needs of the customers. The Technical Office has CAD / CAM systems, with which it is able to carry out the design of the product, the choice of the equipment to be installed on the machine and the needed control checks.

Contact usThe parts produced in our turning department are made both via bar machining (from diam. 20 mm to diam. 70 mm) and by secondary turning with turning capacity up to diam. 300 mm, mainly on CNC lathes but also, in the case of samples, on parallel lathes.

The company has modern transfer machines with rotary tables, with vertical and horizontal axes, and with bar pusher, with several work units and processing stations.

Drilling and milling operations are carried out on horizontal and vertical 3 and 4 axis machining centers set up with rotary tables.

C.T. Centro Tornitura performs mechanical and manual assembly of plastic bushings inside aluminum supports using a special machine with high production capacities.

Quality of our parts is constantly monitored, both on the machine and in the metrology room. The metrology room is equipped with manual and automatic 3D measuring machines.

The Tooling department creates any equipment and measuring instrument necessary for the production. In collaboration with the Technical Office it builds pallets, fixing and testing equipment.

The parts are washed under-vacuum in a low environmental impact process, using the most recent and eco-friendly technology available.